Our Manufacturing Plants

Higashi Matsuyama Plant

ISO 14001 and ISO 9001 Certified Plant

Serving the Saitama, Chiba, Ibaraki and Tochigi prefectural areas as well as the Tohoku and Hokuriku regions, the Higashi Matsuyama Plant provides heat treatment and processing for a range of needs, from mass production to high-mix low-volume production.

Also equipped with high frequency facilities, the Higashi Matsuyama Plant stands ready with to meet the needs of its customers under a production structure as an integrated heat treatment provider.

Available Services

- Carburizing quenching and tempering processing

- Nitrocarburizing quenching and tempering processing

- Bright quenching and tempering processing (general steel for mechanical structures, tool steel, etc.)

- Bright annealing processing

- Gas nitrocarburizing processing

- High frequency quenching and tempering processing

Heating Facilities

| Equipment No. | Standard deposition substance | Manufacturer | Usable Inner Dimensions of Furnace | Maximum Part Weight for Treatment | Maximum Operating Temperature |

|---|---|---|---|---|---|

| B-1 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,520×H740 | 650kg | 950℃ |

| B-2 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,520×H740 | 650kg | 950℃ |

| B-3 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,520×H740 | 650kg | 950℃ |

| B-4 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,520×H740 | 650kg | 950℃ |

| B-5 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-8 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-9 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-10 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-11 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-12 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-13 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-14 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-15 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-16 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-17 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-18 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| N-2 | Allcase gas nitrocarburizing furnace | Nippon Heating | W760×L1,220×H610 | 750kg | 650℃ |

| P-1 | Pit-type gas carburizing furnace | Tokyo Gas | 1,000φ×2,200H | 4,000kg | 1,050℃ |

| P-2 | Pit-type gas carburizing furnace | Tokyo Gas | 1,000φ×2,200H | 4,000kg | 1,050℃ |

| P-3 | Pit-type gas carburizing furnace | Mochizuki Nekki Kogyo | 1,000φ×2,200H | 3,000kg | 1,050℃ |

| P-4 | Pit-type gas carburizing furnace | Mochizuki Nekki Kogyo | 850φ×2,000H | 3,000kg | 1,050℃ |

| P-5 | Pit-type gas carburizing furnace | Mochizuki Nekki Kogyo | 1,000φ×2,000H | 4,000kg | 1,050℃ |

| P-6 | Pit-type gas carburizing furnace | Mochizuki Nekki Kogyo | 850φ×1,600H | 2400kg | 1,150℃ |

| PN-1 | Pit-type gas nitrocarburizing furnace | Mochizuki Nekki Kogyo | 850φ×1,200H | 1,000kg | 650℃ |

Tempering and Heating Facilities

| Equipment No. | Standard deposition substance | Manufacturer | Usable Inner Dimensions of Furnace | Maximum Part Weight for Treatment | Maximum Operating Temperature |

|---|---|---|---|---|---|

| BT-1 | Allcase hot air circulating electric furnace | Chugai Ro | W760×L1,220×H610 | 750kg | 700℃ |

| BT-2 | Allcase hot air circulating electric furnace | kunimitsutekkou | (Double tray type) | 1300kg | 400℃ |

| BT-3 | Allcase hot air circulating electric furnace | Chugai Ro | W760×L1,220×H610 | 750kg | 400℃ |

| BT-4 | Allcase hot air circulating electric furnace | Chugai Ro | W760×L1,220×H610 | 750kg | 700℃ |

| BT-5 | Allcase hot air circulating electric furnace | Chugai Ro | W760×L1,220×H610 | 750kg | 700℃ |

| BT-6 | Allcase bright electric furnace | Chugai Ro | W760×L1,220×H610 | 750kg | 700℃ |

| BT-7 | Allcase bright electric furnace | kunimitsutekkou | (Double tray type) | 1300kg | 400℃ |

| BT-8 | Allcase bright electric furnace | Chugai Ro | W760×L1,220×H610 | 750kg | 400℃ |

| PT-1 | Pit-type hot air circulating electric furnace | Mochizuki Nekki Kogyo | 1,400φ×2,000H | 5,000kg | 700℃ |

| PT-2 | Pit-type hot air circulating electric furnace | Mochizuki Nekki Kogyo | 1,000φ×2,000H | 3,000kg | 700℃ |

| PT-3 | Pit-type hot air circulating electric furnace | Mochizuki Nekki Kogyo | 1,400φ×2,000H | 5,000kg | 700℃ |

| PT-4 | Pit-type hot air circulating electric furnace | Mochizuki Nekki Kogyo | 1,200φ×2,000H | 3,000kg | 700℃ |

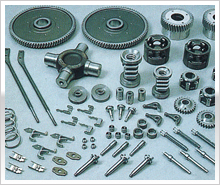

Part prior to being processed by heat treatment

Allcase gas carburizing and hardening furnace

Pit-type gas carburizing furnace

Higashi Matsuyama Plant's High Frequency Line

High Frequency Quenching Facilities

| Oscillator | Quenching machine | Part external diameter (φ) | Stroke (mm) | Weight (kg) |

|---|---|---|---|---|

| FI-1 120KW 20KHz |

F-1 | 20~250 | 1,200 | 200 |

| FI-2 80KW 300KHz |

S-1 | 10~150 | 500 | 30 |

| FI-3 50KW 400KHz |

S-4 | Specialized machine | ||

| FI-4 80KW 400KHz |

F-2 F-4 |

10~180 10~180 |

500 | 30 |

| FI-5 180KW 25・100KHz |

F-5 M-7 S-3 |

10~250 Specialized machine Specialized machine |

900 400 400 |

200 200 30 |

| FI-6 180KW 25・100KHz |

F-6 S-5 |

Specialized machine Specialized machine |

||

| FI-7 100KW 30KHz |

F-8 | 10~100 | 500 | 80 |

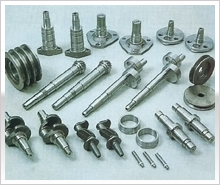

Part prior to being processed using high frequency quenching

High frequency plant’s quenching machine

Robot for high frequency quenching