Our Manufacturing Plants

Atsugi Plant's Aluminum Alloy Heat Treatment Line / Bright Heat Treatment Line

Available Services

- Solution heat treatment quenching and processing

- treatment and processing

- Softening treatment and processing

Vacuum and Bright Treatments

- Magnetic treatment and processing

- Full annealing and processing / Stress-relief annealing and processing

- heat treatment and quenching / hardening treatment and processing of stainless steel

- Quenching and tempering processing of die steel and high-speed tool steel

- Deposition hardening treatment and processing

- Heat treatment and processing of aluminum, titanium, nickel and zirconium

- Brazing treatment and processing

- Gas nitrocarburizing / oxynitriding treatment

- treatment and processing

Bright Treatment Line

Available Services

- Oxynitriding treatment

Low polluting, eco-friendly technology that enables a part to receive nitriding treatment simply by adding ammonia gas and a small amount of oxygen (air) into the furnace. - Oxidized membrane treatment

Produces a thin oxidized membrane of Fe3O4 on the surface of the part, which enhances abrasion resistance and corrosion resistance. In addition to individual treatment, part qualities can also be further enhanced by combining this treatment with gas nitrocarburizing or oxynitriding treatments.

Aluminum / Bright Line Facilities

Aluminum Alloy Heat Treatment Line Processing Facilities

| Equipment No | Name | Manufacturer | Usable Inner Dimensions of Furnace | Maximum Part Weight for Treatment | Maximum Operating Temperature |

|---|---|---|---|---|---|

| PT-7 | Pit-type hot air circulation electric furnace (solution heat treatment furnace) | Mochizuki Nekki Kogyo | 1,500φ×2,100H | 1,500kg | 600℃ |

| PT-9 | Pit-type hot air circulation electric furnace(時効炉) | Mochizuki Nekki Kogyo | 1,500φ×2,100H | 1,500kg | 600℃ |

| PT-11 | Pit-type hot air circulation electric furnace(時効炉) | Mochizuki Nekki Kogyo | 2050φ×2,200H | 2,000kg | 600℃ |

| PT-12 | Pit-type hot air circulation electric furnace(solution heat treatment furnace) | Mochizuki Nekki Kogyo | 1,800φ×3,000H | 2,000kg | 600℃ |

| PT-13 | Pit-type hot air circulation electric furnace(solution heat treatment furnace) | Mochizuki Nekki Kogyo | 2100φ×2,200H | 2,000kg | 600℃ |

| PT-14 | Pit-type hot air circulation electric furnace(solution heat treatment furnace) | Mochizuki Nekki Kogyo | 1,800φ×3,500H | 2,000kg | 600℃ |

| PT-15 | Pit-type hot air circulation electric furnace(時効炉) | Mochizuki Nekki Kogyo | 1,800φ×3,000H | 2,000kg | 600℃ |

| PT-16 | Pit-type hot air circulation electric furnace(時効炉) | Mochizuki Nekki Kogyo | 1,800φ×3,500H | 2,000kg | 600℃ |

Bright Treatment Line Processing Facilities

| Equipment No. | Name | Manufacturer | Usable Inner Dimensions of Furnace | Maximum Part Weight for Treatment | Maximum Operating Temperature |

|---|---|---|---|---|---|

| PT-18 | Non-oxidation annealing furnace (hot air tempering furnace) | Oriental Engineering | 700φ×1,200H | 800kg | 750℃ |

| PV-1 | Gas atmosphere bright annealing furnace | Mochizuki Nekki Kogyo | 850φ×1,200H | 800kg | 950℃ |

| PV-2 | Gas atmosphere bright annealing furnace | Mochizuki Nekki Kogyo | 1,000φ×1,200H | 1,000kg | 900℃ |

| PV-3 | Gas atmosphere bright annealing furnace | Mochizuki Nekki Kogyo | 900φ×1,000H | 1,000kg | 900℃ |

| PV-4 | Gas atmosphere bright annealing furnace | Shinei Netsu Kogyo | 12,00φ×2,400H | 3,000kg | 900℃ |

| PV-5 | Gas atmosphere bright annealing furnace | Mochizuki Nekki Kogyo | 1,400φ×1,600H | 6,500kg | 930℃ |

| PNT-1 | Pit-type nitriding furnace | Control equipment: Nippon S.T. Johnson Sales Furnace: Mochizuki Nekki Kogyo |

850φ×1,200H | 1,000kg | 750℃ |

| PN-2 | Gas oxynitriding and nitrocarburizing furnace | Mochizuki Nekki Kogyo | 1,000φ×1,000H | 800kg | 750℃ |

| PN-3 | Gas oxynitriding and nitrocarburizing furnace | Mochizuki Nekki Kogyo | 900φ×1,000H | 500kg | 900℃ |

Atmosphere heat treatment and processing facility (hydrogen atmosphere annealing furnace)

| Equipment No. | Name | Manufacturer | Retort dimensions | Atmosphere | Maximum Operating Temperature |

|---|---|---|---|---|---|

| H-1 | Horizontal atmosphere furnace | Mochizuki Nekki Kogyo | 206φ×1,500L | N2H2 | 950℃ |

Other Facilities

| Fl-1 | Other Facilities | Nippon Thermonics | Output 30kW | 200kHz |

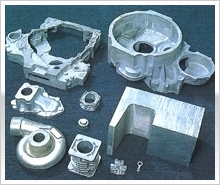

Aluminum part processed by heat treatment

Aluminum heat treatment furnace

Pit-type nitriding furnace