Our Manufacturing Plants

Atsugi Plant

ISO 14001 and ISO 9001 Certified Plant

Serving the Kanagawa, Tokyo, Yamanashi, Shizuoka and Chiba prefectural areas, the Atsugi Plant provides heat treatment and processing using its wealth of technical competencies and thorough quality control system. The plant handles everything from oversized parts to compact components, and from mass production to single piece production.

Available Services

- Carburizing quenching and processing

- Nitrocarburizing quenching and processing

- Vacuum carburizing quenching and processing

- Bright quenching and processing (steel for general mechanical structures, tool steel, etc.)

- Bright annealing and processing

- Gas carbonitriding and processing

- Boronizing treatment and processing

- Shot peening

Carburizing Line Facilities

| Equipment No. | Name | Manufacturer | Usable Inner Dimensions of Furnace | Maximum Part Weight for Treatment | Maximum Operating Temperature |

|---|---|---|---|---|---|

| B-1 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,520×H740 | 1,000kg | 950℃ |

| B-2 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,520×H740 | 1,000kg | 950℃ |

| B-3 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,520×H740 | 1,000kg | 950℃ |

| B-4 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,520×H740 | 1,000kg | 950℃ |

| B-5 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-6 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-7 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-8 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-9 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-10 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-11 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| B-12 | Allcase gas carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| CV-1 | Vacuum carburizing quenching furnace | Chugai Ro | W760×L1,220×H640 | 650kg | 950℃ |

| BT-1 | Electrothermal heavy-type hot air circulating tempering furnace | Chugai Ro | W760×L1,520×H740 | 1000kg | 700℃ |

| BT-2 | Electrothermal super-sized hot air circulating tempering furnace | Chugai Ro | W760×L1,220×H610 | 750kg | 700℃ |

| BT-3 | Electrothermal super-sized hot air circulating tempering furnace | Chugai Ro | W760×L1,220×H610 | 750kg | 700℃ |

| HSZ | Subzero tank | Teisan | W1500×L1,520×H700 | 1000kg | -80℃ |

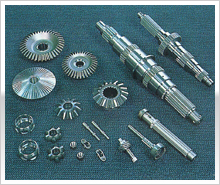

Processed parts

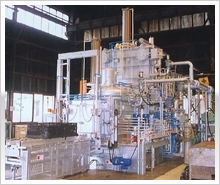

Automated Allcase gas carburizing quenching furnace

Vacuum carburizing quenching furnace

Heating Equipment

| Equipment No. | Name | Manufacturer | Usable Inner Dimensions of Furnace | Maximum Part Weight for Treatment | Maximum Operating Temperature |

|---|---|---|---|---|---|

| P-3 | Pit-type gas carburizing furnace | Mochizuki Nekki Kogyo | 1,500φ×3,000H | 15,000kg | 1,030℃ |

| P-4 | Pit-type gas carburizing furnace | Mochizuki Nekki Kogyo | 1,500φ×3,000H | 15,000kg | 1,030℃ |

| P-5 | Pit-type gas carburizing furnace | Tokyo Gas Engineering | 1,500φ×3,000H | 15,000kg | 1,030℃ |

| P-6 | Pit-type gas carburizing furnace | Tokyo Gas Engineering | 1,300φ×1,800H | 3,000kg | 1,030℃ |

| PT-2 | Pit-type hot air circulating tempering furnace | Mochizuki Nekki Kogyo | 1,200φ×2,000H | 2,500kg | 700℃ |

| PT-3 | Pit-type hot air circulating tempering furnace | Mochizuki Nekki Kogyo | 1,200φ×2,000H | 2,500kg | 700℃ |

| PT-4 | Pit-type hot air circulating tempering furnace | Mochizuki Nekki Kogyo | 760φ×1,000H | 1,000kg | 700℃ |

| PT-5 | Pit-type hot air circulating tempering furnace | Mochizuki Nekki Kogyo | 1,500φ×3,000H | 5,000kg | 750℃ |

| PT-6 | Pit-type hot air circulating tempering furnace | Mochizuki Nekki Kogyo | 1,600φ×3,500H | 15,000kg | 750℃ |

The Atsugi Plant offers non-ferrous metal heat treatment for aluminum alloy castings, forged parts, expanded materials and die cast parts, magnesium alloy and copper alloy.

It also features bright heat treatment facilities and vacuum heat treatment facilities, which enables us to offer heat treatments for specialty metals as well.

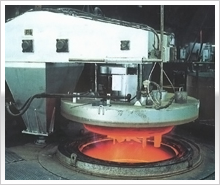

Pit-type gas carburizing furnace

Pit-type gas carburizing furnace

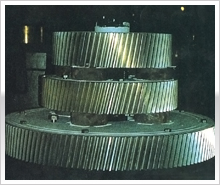

Oversized gear prior to being processed by heat treatment

Anti-carburized oversized pinion gear (weight: 4 tons)

Fully automated bending correction machine

Shot peening machine